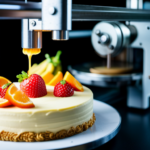

Like sculpting with liquid silk, mastering the art of 3D printed chocolate creations requires a delicate balance of precision and creativity.

From understanding the properties of chocolate to selecting the perfect temperature, this article provides expert guidance on achieving flawless results.

Whether you are a chocolatier looking to elevate your craft or a confectionery enthusiast eager to explore the world of edible art, these tips will help you create stunning and delectable masterpieces.

Understanding Chocolate’s Properties

While 3D printing chocolate may seem like a simple process, it requires a deep understanding of chocolate’s properties to achieve successful results. One crucial property to consider is the melting point of chocolate. Different types of chocolate have varying melting points, affecting the printing process. For instance, dark chocolate melts at a higher temperature than milk chocolate. Understanding the specific melting point of the chocolate being used is essential for adjusting the printing parameters accordingly.

Another critical aspect is the crystallization behavior of chocolate. Chocolate can form six different crystal structures, but the key for 3D printing is to achieve the most stable form, known as Form V. This form ensures that the chocolate sets correctly and maintains its shape once printed. Adjusting tempering processes and temperatures can influence the crystallization behavior, ultimately impacting the print quality and structural integrity of the final product.

Selecting the Right Chocolate

When it comes to 3D printed chocolate creations, selecting the right chocolate is crucial. The cocoa content of the chocolate will affect its viscosity and texture, which are important considerations for successful 3D printing.

Additionally, the potential for flavor infusion opens up a world of creative possibilities for unique and delicious chocolate creations.

Cocoa Content Considerations

The cocoa content of the chocolate used in 3D printed creations significantly impacts the final taste, texture, and printability. When considering cocoa content for 3D printed chocolate, it is essential to take into account:

-

Flavor Balance: Higher cocoa content tends to result in a more intense and slightly bitter chocolate flavor, while lower cocoa content yields a sweeter and milder taste. Achieving the right balance is crucial for a delightful consumer experience.

-

Melting Point: Cocoa content affects the melting point of chocolate. Higher cocoa content chocolate has a higher melting point, making it more suitable for intricate 3D designs with finer details.

-

Printability: The right cocoa content ensures that the chocolate maintains its shape during printing, producing precise and accurate designs.

Understanding these considerations is key to selecting the perfect chocolate for 3D printing delectable creations.

Viscosity and Texture

Selecting the appropriate chocolate with optimal viscosity and texture is critical for ensuring the successful 3D printing of intricate and delectable chocolate creations. Texture control and printing precision are directly influenced by the viscosity management and structural integrity of the chocolate used. When choosing a chocolate for 3D printing, it’s essential to consider its cocoa content, fat content, and any additional flavorings or additives. The table below provides a comparison of different types of chocolate based on their viscosity, texture, and suitability for 3D printing.

| Chocolate Type | Viscosity | Texture | Suitability |

|---|---|---|---|

| Dark Chocolate | High | Smooth | Excellent |

| Milk Chocolate | Medium | Creamy | Good |

| White Chocolate | Low | Rich | Fair |

Flavor Infusion Options

To ensure the successful 3D printing of chocolate creations, it is essential to consider various flavor infusion options as a continuation of our discussion on viscosity and texture management. When selecting the right chocolate for 3D printing, it’s important to consider flavor pairing and infusion methods to achieve the desired taste and texture. Here are some key factors to consider:

-

Flavor Pairing: Choose chocolate flavors that complement the intended infusion, such as dark chocolate for robust flavors like coffee or chili, and milk chocolate for sweeter infusions like caramel or fruit.

-

Infusion Methods: Explore infusion techniques like cold or hot infusion, where flavors are incorporated into the chocolate before the printing process, ensuring a consistent and balanced taste throughout the creation.

-

Quality Control: Select high-quality chocolate with a smooth consistency, essential for successful 3D printing and flavor infusion.

Mastering 3D Printing Techniques

Mastering 3D printing involves understanding the intricacies of layer deposition and material extrusion to achieve precision and quality in chocolate creations. When it comes to 3D printing chocolate, mastering the techniques is essential for creating intricate and delectable designs. Here are some key aspects to consider when mastering 3D printing techniques for chocolate creations:

| Key Aspect | Description |

|---|---|

| Layering Techniques | Understanding the optimal layer height and infill density is crucial for achieving precise and visually appealing chocolate designs. Utilizing advanced layering techniques can enhance the structural integrity of the printed chocolate. |

| 3D Modeling | Proficiency in 3D modeling software is essential for creating intricate and customized designs for 3D printed chocolate. Mastering the art of digital sculpting and CAD design allows for limitless creativity in chocolate confections. |

| Food Safe Materials | Utilizing food-safe 3D printing materials is paramount for ensuring that the printed chocolate remains edible and safe for consumption. Understanding the properties of food-safe filaments and their impact on the final chocolate product is crucial. |

| Printing Speed | Balancing printing speed with quality is important in 3D printing chocolate. Mastering the optimal printing speed can significantly affect the final texture and visual appeal of the chocolate creations. |

Mastering these 3D printing techniques is essential for achieving exceptional results in creating 3D printed chocolate confections.

Designing Intricate Chocolate Creations

How can intricate designs elevate the visual appeal of 3D printed chocolate creations?

Chocolate sculpting allows for the creation of intricate and detailed designs that can captivate the eye and delight the palate. When designing intricate chocolate creations, consider the following:

-

Custom Molds: Utilize custom molds to create unique and detailed shapes, such as delicate filigree patterns or intricate floral designs. These molds can be tailored to your specific vision, enabling you to bring even the most elaborate designs to life in chocolate form.

-

Intricate Patterns: Custom molds provide the opportunity to incorporate intricate patterns, such as lace or geometric designs, into your chocolate creations, adding a touch of elegance and sophistication.

-

Fine Details: With custom molds, it’s possible to capture fine details, such as intricate textures and embossed designs, enhancing the visual appeal and overall artistry of the chocolate sculptures.

By leveraging chocolate sculpting techniques and custom molds, artisans can produce visually stunning and finely detailed chocolate creations that are sure to impress. These intricate designs not only enhance the aesthetic appeal but also showcase the artistry and skill involved in 3D printed chocolate creations.

Now, let’s delve into the crucial considerations of temperature and humidity when perfecting 3D printed chocolate creations.

Temperature and Humidity Considerations

When it comes to 3D printing chocolate, temperature control is crucial for ensuring the quality and consistency of the final product.

Additionally, the impact of humidity levels cannot be overlooked, as it can affect the texture and overall performance of the chocolate during the printing process.

Understanding and managing these factors is essential for achieving successful and flawless 3D printed chocolate creations.

Temperature Control for Quality

Maintaining precise temperature and humidity levels is crucial for achieving high-quality 3D printed chocolate creations.

- Temperature Consistency

- Utilize advanced cooling methods such as rapid cooling chambers or precise temperature-controlled storage units to ensure the chocolate maintains the ideal temperature throughout the printing process.

- Monitor the temperature of the printing environment closely to prevent fluctuations that could compromise the texture and structure of the chocolate during printing.

- Implement innovative technologies like thermal imaging to identify and rectify any temperature inconsistencies in real-time, ensuring the chocolate remains in its optimal state for printing.

Ensuring temperature consistency is just the beginning when it comes to perfecting 3D printed chocolate creations. Now, let’s delve into the impact of humidity levels on the printing process.

Impact of Humidity Levels

The impact of humidity levels on the 3D printing process for chocolate creations is a critical consideration for achieving optimal results. Humidity can significantly affect the quality of 3D printed chocolate, making moisture management essential in the production process.

High humidity levels can introduce excess moisture to the chocolate, leading to issues such as clogging in the printer nozzle, poor layer adhesion, and a dull, unappealing finish.

On the other hand, low humidity levels can cause the chocolate to dry out too quickly, resulting in a brittle and crumbly texture.

To mitigate these humidity effects, it’s crucial to control the moisture content in the printing environment. This can be achieved through proper storage of chocolate, using dehumidifiers, and maintaining stable environmental conditions to ensure consistent and high-quality 3D printed chocolate creations.

Finishing and Presentation Tips

Utilizing carefully selected finishing techniques and exquisite presentation methods is essential for showcasing the artistry and quality of 3D printed chocolate creations. To elevate the visual and sensory experience of your chocolate masterpieces, consider the following finishing and presentation tips:

-

Presentation Techniques: When presenting 3D printed chocolate creations, consider using elegant serving platters or decorative stands to enhance the overall visual appeal. Incorporating creative garnishes such as edible flowers, gold leaf accents, or delicate sugar sculptures can add a touch of sophistication to your presentation.

-

Texture Contrast: Experiment with incorporating contrasting textures into your presentation to create visual interest. Pair smooth, glossy chocolate sculptures with crunchy elements like caramelized nuts or delicate chocolate shavings to add an element of surprise and delight to the overall experience.

-

Color Contrast: Pay attention to color contrast when arranging your 3D printed chocolate creations. Consider pairing rich, dark chocolate sculptures with vibrant, contrasting elements such as fresh berries or colorful edible powders to create visually stunning and appetizing displays.

Frequently Asked Questions

Can 3D Printed Chocolate Creations Be Stored for Long Periods of Time, and if So, What Is the Best Way to Do So?

3D printed chocolate creations can be stored for several months when kept in a cool, dry place away from sunlight and strong odors. Vacuum-sealing or wrapping in foil can help preserve their quality.

Are There Any Special Considerations or Techniques for Creating 3D Printed Chocolate Creations With Fillings or Layered Designs?

When creating 3D printed chocolate creations with fillings or layered designs, it’s crucial to consider the viscosity of the fillings and the structural integrity of the layers. Using proper filling techniques and strategic layering is essential for achieving high-quality results.

How Can 3D Printed Chocolate Creations Be Customized With Different Flavors or Colors?

Customized flavors and color variations in 3D printed chocolate creations can be achieved by using different types of chocolate, flavor extracts, and food coloring. Texture preferences and unique designs can also be incorporated for a personalized touch.

What Are Some Tips for Troubleshooting Common Issues That May Arise When 3D Printing With Chocolate, Such as Clogging or Inconsistent Flow?

Troubleshooting chocolate clogging and inconsistent flow in 3D printing involves adjusting print settings and carefully managing chocolate temperature. To address clogging, consider increasing nozzle diameter, while for flow issues, experiment with layer height and print speed.

Are There Any Specific Safety or Hygiene Considerations to Keep in Mind When Working With 3D Printed Chocolate, Especially if It Will Be Consumed?

When working with 3D printed chocolate, it is essential to prioritize safety precautions and adhere to strict hygiene standards, especially if the confections are intended for consumption. This ensures the quality and safety of the final product.

Conclusion

In conclusion, perfecting 3D printed chocolate creations requires:

- A deep understanding of chocolate’s properties

- Careful selection of the right chocolate

- Mastering 3D printing techniques

- Designing intricate creations

- Considering temperature and humidity

- Paying attention to finishing and presentation.

While some may find the process of 3D printing chocolate to be daunting, with the right knowledge and techniques, anyone can create stunning and delicious chocolate creations that will impress and delight.