As the demand for personalized and intricate food designs surges, the integration of 3D printing technology in the culinary industry has become increasingly prevalent.

However, ensuring the seamless operation and safe production of food 3D printers requires diligent maintenance and care.

This article provides a comprehensive guide to cleaning, troubleshooting, and calibrating these innovative devices, offering essential tips for preventing issues and maintaining food safety compliance.

Cleaning and Sanitizing Procedures

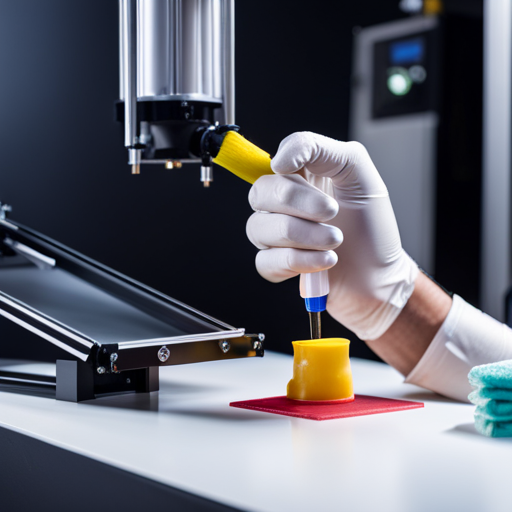

When cleaning and sanitizing food 3D printers, it is essential to follow specific procedures to ensure the safety and quality of the printed food products.

Cleaning equipment used for food 3D printers should be designed for food industry use and should be thoroughly cleaned before and after each use.

It is crucial to use cleaning solutions that are safe for food contact surfaces and to follow the manufacturer’s instructions for proper dilution and application.

Sanitizing surfaces that come into contact with food is critical to prevent the growth of harmful bacteria. This can be achieved by using food-safe sanitizing solutions or heat treatments.

Surfaces should be regularly inspected for any signs of wear or damage that could affect the quality and safety of the printed food.

Additionally, it is important to establish a regular cleaning and maintenance schedule to ensure that the food 3D printer remains in optimal condition.

Following these cleaning and sanitizing procedures diligently is imperative to uphold food safety standards and produce high-quality printed food products.

Troubleshooting Common Printer Issues

How can food 3D printer operators efficiently address common printer issues to ensure uninterrupted production and consistent quality? Printer troubleshooting is a critical aspect of maintaining a smooth workflow in food 3D printing. Here are some essential troubleshooting techniques and problem-solving strategies:

-

Calibration: Regularly calibrating the printer ensures that the printing components are properly aligned, preventing issues such as misprints and layer adhesion problems.

-

Filament Jamming: Clearing any filament jams promptly can prevent disruptions in the printing process and avoid damage to the printer’s extruder.

-

Temperature Control: Monitoring and adjusting the print bed and extruder temperatures can help prevent issues such as warping, under-extrusion, or overheating.

-

Software Updates: Ensuring that the printer’s firmware and slicing software are up to date can resolve compatibility issues and improve overall printing performance.

Preventative Maintenance Tips

Implementing regular maintenance is crucial for ensuring the longevity and reliability of food 3D printers. Preventative maintenance plays a significant role in minimizing downtime and extending the lifespan of the equipment. To effectively maintain a food 3D printer, the following preventative maintenance tips should be observed:

| Maintenance Task | Frequency | Description |

|---|---|---|

| Lubrication Techniques | Every 100 hours | Apply food-grade lubricant to the moving parts |

| Storage Precautions | As needed | Store the printer in a clean, dry environment |

| Wear and Tear Assessment | Monthly | Inspect components for signs of wear and tear |

| Replacement Schedule | As recommended | Replace worn-out parts based on manufacturer guidelines |

Lubrication techniques involve applying food-grade lubricants to the moving parts, ensuring smooth operation and preventing friction-related damage. Additionally, regular assessment of wear and tear allows for timely replacement of worn-out components, minimizing the risk of unexpected breakdowns. Proper storage precautions, such as keeping the printer in a clean, dry environment, also contribute to the printer’s longevity. These maintenance tasks are essential for optimal printer performance and durability. Now, let’s delve into the crucial aspect of calibrating the 3D printer.

Calibrating the 3D Printer

What factors should be considered when calibrating a food 3D printer for optimal performance and accuracy?

Calibrating a food 3D printer is crucial for ensuring precise and high-quality prints. When calibrating the printer, several factors need to be carefully considered:

-

Leveling Bed: Properly leveling the bed is essential to ensure that the print adheres uniformly to the print surface. This prevents issues such as warping and uneven layer height, resulting in more accurate prints.

-

Adjusting Nozzle: The nozzle must be accurately adjusted to the correct height above the print bed. This adjustment is critical for achieving the right layer adhesion and preventing nozzle clogging, ensuring the consistent extrusion of food materials.

-

Checking Extrusion Rate: Calibrating the extrusion rate is vital for achieving accurate dimensions and infill density in printed food items. It ensures that the right amount of material is extruded, resulting in precise and consistent prints.

-

Fine-tuning Temperature Settings: Precise temperature control is essential when working with food materials. Calibrating the temperature settings ensures that the food is extruded at the optimal temperature, preventing issues such as under-extrusion or overheating.

Ensuring Food Safety Compliance

When ensuring food safety compliance in the context of maintaining and caring for food 3D printers, meticulous attention to hygiene and sanitation protocols is paramount.

Ensuring temperature accuracy during the printing process is essential to prevent bacterial growth and foodborne illnesses. Regular calibration and verification of the printer’s temperature controls are necessary to guarantee that the food is cooked or processed at the correct temperatures.

Additionally, verifying ingredient quality is crucial to prevent contamination and ensure that the printed food meets regulatory standards. All ingredients used in the 3D printing process must be sourced from reputable suppliers and undergo rigorous quality checks before being used in the printer.

Furthermore, implementing a comprehensive cleaning and sanitation schedule for the printer, its components, and the surrounding work area is imperative to minimize the risk of cross-contamination.

Adhering to these stringent food safety measures is vital to uphold the highest standards of quality and safety in the production of 3D printed food.

Frequently Asked Questions

Can I Use the Same Cleaning and Sanitizing Procedures for Both Sweet and Savory Food 3D Printers?

When considering cleaning procedures for sweet and savory food 3D printers, it’s critical to prevent cross-contamination. Different ingredients and residues may require distinct cleaning and sanitizing methods to ensure food safety and maintain the integrity of the printed products.

How Can I Prevent Clogs and Jams in My Food 3D Printer When Using Different Types of Ingredients?

To prevent clogs and jams in food 3D printers when using different types of ingredients, it is essential to ensure ingredient compatibility and prevent cross-contamination. Regular cleaning, using appropriate materials, and following manufacturer guidelines are crucial for maintaining optimal printer performance.

What Are Some Common Signs That Indicate My Food 3D Printer May Need Maintenance?

Common signs indicating food 3D printer maintenance needs include inconsistent print quality, unusual noises, and extruder issues. Regular maintenance and inspection, along with printer calibration and troubleshooting, are essential for preventing and addressing these issues.

Are There Any Specific Temperature and Humidity Requirements for Calibrating a Food 3D Printer?

Temperature requirements and humidity considerations are crucial for calibrating a food 3D printer. The ideal temperature range for calibration is typically between 20-25°C, while maintaining humidity levels at 40-60% to ensure optimal printing conditions and quality output.

How Can I Ensure That My Food 3D Printer Is Compliant With Food Safety Regulations When Using Custom Recipes and Ingredients?

When customizing recipes and ingredients for food 3D printing, ensuring compliance with food safety regulations is paramount. Robust temperature regulation and humidity control are essential for maintaining ingredient safety and print quality.

Conclusion

In conclusion, maintaining and caring for food 3D printers is essential for ensuring food safety compliance and preventing common printer issues.

Regular cleaning and sanitizing, troubleshooting, preventative maintenance, and calibration are all vital aspects of printer care.

Following these procedures diligently will guarantee the longevity and efficiency of the printers, ultimately leading to better quality and safe food production.