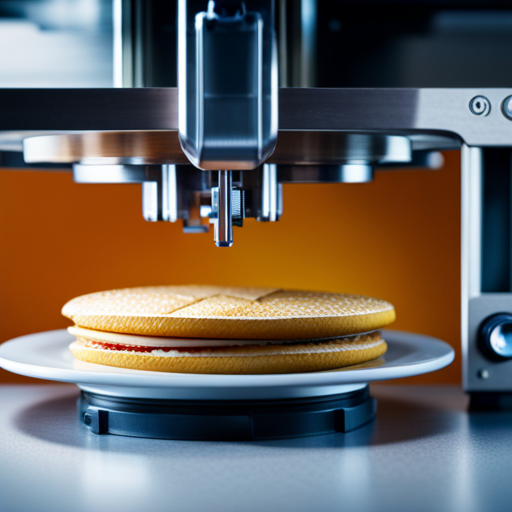

While some may argue that traditional food preparation methods are irreplaceable, the latest advancements in food 3D printer software are revolutionizing the culinary landscape.

This article provides an in-depth review of the most cutting-edge innovations in food 3D printer software, from enhanced user interfaces to real-time monitoring and control features.

As technology continues to evolve, these advancements offer exciting possibilities for customizable and efficient food production.

Enhanced User Interface

The enhanced user interface of the latest food 3D printer software provides a more intuitive and efficient experience for operators and designers. This improvement has significantly enhanced the overall user experience, making it easier for operators to navigate the software and for designers to create intricate food designs with precision. The new interface offers a seamless and user-friendly design, prioritizing functionality and ease of use. With streamlined menus and simplified navigation, users can now access various tools and features more effortlessly, ultimately improving productivity and workflow.

Furthermore, the updated software interface has been designed with a focus on enhancing the design process, offering a range of customizable design options. These options empower designers to unleash their creativity and bring unique food designs to life. By seamlessly integrating customizable design options within the user interface, the software enables designers to experiment with different textures, shapes, and patterns, ultimately expanding the possibilities for food 3D printing.

This seamless transition from user experience and interface functionality to customizable design options ensures a holistic and efficient approach to food 3D printing.

Customizable Design Options

Enhancing creativity through customizable design options is a key feature of the latest food 3D printer software, catering to the diverse needs of designers and expanding possibilities for food 3D printing. The design flexibility offered by these software solutions empowers users to unleash their creativity and bring intricate culinary concepts to life.

Some of the customizable design options include:

-

Shape Customization: Users can manipulate the shape and size of food items, enabling them to create unique and personalized culinary designs.

-

Texture Variation: The software allows for adjusting the texture of printed food, offering options for smooth, crunchy, or other desired textures to be incorporated into the final product.

-

Color Customization: With the ability to customize the color of printed food, designers can craft visually appealing and vibrant dishes, enhancing the overall presentation and customer experience.

These customizable design options not only provide creative possibilities but also open doors to experimentation and innovation in the culinary world. The software’s capabilities in this aspect enable chefs and food designers to push the boundaries of traditional food presentation and create truly one-of-a-kind dining experiences.

Improved Printing Speed

With a 30% increase in printing speed, the latest advancements in food 3D printer software are revolutionizing the efficiency of culinary production. Printing optimization and speed enhancements have become key focal points for developers, aiming to streamline the food 3D printing process. These improvements are a game-changer for professional kitchens and food production facilities, where time is of the essence.

The printing optimization features in the latest software versions have significantly reduced the time required to print complex food designs. This has been made possible through advanced algorithms that analyze the printing path and optimize it for maximum efficiency. As a result, chefs and food manufacturers can now produce intricate 3D food designs in a fraction of the time previously required.

Speed enhancements in food 3D printer software have not only accelerated the printing process but also improved the overall productivity of culinary operations. With faster printing speeds, businesses can fulfill orders more quickly, reduce waiting times, and ultimately enhance customer satisfaction. The impact of these software innovations is profound, as they empower the food industry to meet the increasing demands for customized and visually stunning culinary creations.

Advanced Material Compatibility

The advancements in food 3D printer software have opened up new material options, allowing for enhanced printing capabilities. These developments have enabled the compatibility of a wider range of materials, providing more flexibility and versatility in food printing applications.

With improved material compatibility, food 3D printers can now handle various ingredients and textures, expanding the possibilities for creating innovative culinary experiences.

New Material Options

Advanced material compatibility is a key consideration for the latest innovations in food 3D printer software. The introduction of new material options enhances material flexibility and printing quality, allowing for a wider range of ingredients to be utilized in 3D food printing.

This innovation contributes to sustainability and cost-effectiveness, as it enables the utilization of alternative, eco-friendly ingredients and reduces waste in food production. The advancements in material options also facilitate the creation of customized nutritional profiles and textures, meeting the diverse dietary requirements of consumers.

Moreover, these developments open doors for the use of unconventional ingredients, promoting creativity and innovation in the culinary industry.

Enhanced Printing Capabilities

The enhanced printing capabilities of the latest innovations in food 3D printer software significantly improve material compatibility, expanding the range of ingredients that can be utilized for 3D food printing. This advancement not only enhances printing quality but also increases material strength, allowing for the creation of more intricate and durable food designs. The table below provides an overview of the enhanced printing capabilities and their impact on material compatibility.

| Enhanced Printing Capabilities | Impact on Material Compatibility | Benefits |

|---|---|---|

| Advanced material compatibility | Expanded range of ingredients | Diverse food options |

| Improved printing precision | Enhanced printing quality | Finer details in food designs |

| Increased material strength | Sturdier food constructs | Long-lasting food products |

Intuitive Software Integration

Intuitive software integration in food 3D printer software is critical for a seamless user experience.

A user-friendly interface design allows for easy navigation and efficient operation, while seamless workflow integration ensures that the software aligns with existing processes and systems.

These points are essential for maximizing the potential of food 3D printer software and enhancing overall productivity in food printing operations.

User-Friendly Interface Design

An essential aspect of food 3D printer software is the development of a user-friendly interface design that enhances intuitive software integration. To achieve this, software developers are focusing on the following key elements:

- Intuitive Navigation: Implementing easy-to-use menus and navigation tools to ensure seamless user interaction.

- Interactive Tutorials: Providing step-by-step guides and tutorials within the software to assist users in understanding its functionalities.

- Visual Feedback: Incorporating visual cues and feedback mechanisms to enhance user understanding and interaction with the software.

Seamless Workflow Integration

Fostering seamless workflow integration is pivotal to the advancement of food 3D printer software, ensuring a cohesive and user-centric experience. Integration optimization plays a crucial role in streamlining the entire 3D food printing process.

By seamlessly integrating with existing software and hardware systems, 3D food printer software can facilitate workflow automation, reducing manual intervention and increasing operational efficiency. This integration also enables the synchronization of data and processes across different stages of food printing, from recipe creation to final production.

Through intuitive software integration, users can experience a seamless transition between design, preparation, and printing, ultimately enhancing productivity and reducing potential errors. As the technology continues to evolve, prioritizing seamless workflow integration in food 3D printer software remains essential for the industry’s growth and development.

Precision and Accuracy Upgrades

Improving precision and accuracy in food 3D printer software requires meticulous attention to detail and constant refinement. To achieve this, the following key areas have seen significant advancements:

-

Calibration Improvements: Recent developments have focused on refining the calibration process, ensuring that the printer’s components are precisely aligned and configured for optimal performance.

-

Accuracy Enhancements: Software updates have enabled more accurate translation of digital designs into physical objects, minimizing discrepancies between the intended and actual output.

-

Layer Thickness Adjustments: Innovations in software now allow for finer control over layer thickness, resulting in smoother and more detailed prints.

These advancements in precision and accuracy have greatly contributed to the overall quality and reliability of food 3D printing. By addressing these crucial aspects, manufacturers and users can expect more consistent and refined results, ultimately advancing the potential applications of 3D printed food.

Now, let’s delve into the subsequent section about ‘enhanced recipe management’.

Enhanced Recipe Management

How can enhanced recipe management streamline food 3D printing processes and improve overall efficiency?

By incorporating advanced recipe optimization and ingredient tracking features, food 3D printer software can significantly enhance the management of recipes, leading to improved efficiency and precision in the printing process.

These features allow for the precise control of ingredient proportions, ensuring the accurate replication of desired food items. Recipe optimization tools enable the customization of printing parameters, such as texture, flavor, and nutritional content, leading to a more tailored and consistent end product.

Ingredient tracking capabilities provide real-time monitoring of inventory levels, alerting users to low stock and expirations, thus preventing printing delays due to missing or spoiled ingredients.

By seamlessly integrating these features, the software can streamline the entire production process, from recipe creation to printing, enhancing overall efficiency and reducing wastage.

This enhanced recipe management not only optimizes food 3D printing processes but also facilitates quality control, ensuring that the final printed products meet the desired standards.

Furthermore, real-time monitoring and control functionalities complement enhanced recipe management by providing immediate oversight of the printing process, ensuring precision and accuracy.

Real-time Monitoring and Control

Real-time monitoring and control functionalities complement enhanced recipe management by providing immediate oversight of the printing process, ensuring precision and accuracy in food 3D printing. This feature allows for quality control measures to be implemented in real-time, enabling operators to promptly address any deviations from the desired printing parameters.

Additionally, remote access capabilities enable users to monitor and adjust the printing process from any location, enhancing convenience and flexibility in managing 3D food printing operations.

Furthermore, real-time monitoring and control features facilitate the seamless integration of sensor data, allowing for continuous feedback and adjustment to optimize printing outcomes.

Frequently Asked Questions

Can 3D Food Printer Software Be Integrated With Existing Kitchen Appliances and Systems?

Integration challenges arise in integrating 3D food printer software with existing kitchen appliances and systems. Compatibility testing is crucial to ensure seamless operation. This process must account for different hardware and software specifications to achieve optimal integration.

Are There Any Special Considerations for Printing With Certain Types of Food Materials, Such as Liquid or Delicate Ingredients?

When working with a food 3D printer, special considerations for printing with liquid ingredients and delicate materials are vital. Maintaining precise temperature control and optimizing printing speed are crucial for achieving high-quality results.

How Does the Software Manage and Adjust for Variations in Ingredient Density and Consistency?

The software manages ingredient consistency by utilizing advanced algorithms to adjust printing parameters based on variations in density and texture. This ensures precise control over the 3D printing process, resulting in accurate and high-quality food creations.

Can the Software Accommodate Personalized Dietary Preferences and Restrictions, Such as Gluten-Free or Vegan Options?

The software offers extensive personalized customization capabilities to accommodate dietary restrictions such as gluten-free or vegan options. It seamlessly manages food compatibility and ingredient consistency. Moreover, it provides robust technical support and troubleshooting resources for user convenience.

What Kind of Support and Troubleshooting Resources Are Available for Users Who May Encounter Technical Issues With the Software?

Users of the software have access to robust support and troubleshooting resources. This includes comprehensive user training to address technical issues. Additionally, online forums provide a platform for users to seek assistance and share experiences.

Conclusion

In conclusion, the latest reviews of innovations in food 3D printer software reveal significant enhancements in:

- User interface

- Design options

- Printing speed

- Material compatibility

- Software integration

- Precision

- Accuracy

- Recipe management

- Real-time monitoring

These advancements are pushing the boundaries of 3D food printing technology, making it more accessible and efficient.

As we continue to embrace these cutting-edge updates, the future of food printing looks promising, with the potential to revolutionize the way we prepare and consume meals.

The era of food printing is upon us.