Step into the future of culinary innovation as we explore the tantalizing world of food 3D printing in professional kitchens.

Imagine a world where delectable dishes are crafted with precision and artistry, using cutting-edge technology to elevate the dining experience.

In this article, we delve into the evolution, benefits, applications, and considerations of food 3D printing, shedding light on its promising future in the culinary arts.

The Evolution of Food 3D Printing

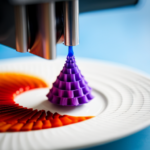

The evolution of food 3D printing has seen advancements in technology, materials, and culinary applications. 3D printing technology has rapidly progressed, enabling chefs to explore new dimensions of culinary innovation. Initially used for creating decorative food items, 3D printing in professional kitchens has now expanded to include a wide range of applications, such as customizing textures, flavors, and nutritional content.

The integration of 3D printing in professional kitchens has revolutionized the way chefs approach food presentation and creation. With the ability to precisely control ingredient placement and design intricate structures, chefs can now elevate the visual and textural elements of their dishes. This technology has also paved the way for enhancing culinary innovation by enabling the production of complex shapes and designs that were previously unattainable through traditional methods.

Moreover, the materials used in food 3D printing have evolved to include a variety of edible substances, ranging from chocolate and sugar to dough and vegetable-based pastes. This expansion of printable materials further underscores the potential for culinary creativity and customization, allowing chefs to craft unique and visually stunning dishes that captivate both the eyes and the palate.

Benefits of Food 3D Printing

Indisputably, food 3D printing offers professional kitchens unparalleled opportunities for creativity and precision in culinary design. The benefits of food 3D printing are vast, providing customizable creations and time-saving efficiencies that revolutionize the way food is prepared and presented.

Some of the key advantages include:

-

Customizable Creations: Food 3D printing allows chefs to create intricate and personalized designs that were previously impossible with traditional methods. This opens up a new world of possibilities for unique dishes and artistic presentations.

-

Precision and Consistency: 3D printers ensure precise measurements and consistent portions, resulting in uniformity across dishes. This level of accuracy is challenging to achieve manually and enhances the overall dining experience.

-

Time Saving Efficiencies: By automating certain aspects of food preparation, 3D printing can significantly reduce the time required to produce complex components or decorative elements, allowing chefs to focus on other aspects of their craft.

-

Waste Reduction: With the ability to precisely control ingredient quantities, food 3D printing minimizes waste, leading to cost savings and a more sustainable kitchen operation.

-

Innovative Menu Offerings: Chefs can experiment with unconventional ingredients and textures, pushing the boundaries of culinary artistry and offering diners truly unique gastronomic experiences.

Applications in Professional Kitchens

Food 3D printing in professional kitchens offers a wide range of applications that leverage its ability to create intricate designs, precise measurements, and innovative menu offerings. One of the primary applications is the creation of a customized menu. 3D printing allows chefs to tailor dishes to meet individual preferences and dietary restrictions, providing a unique and personalized dining experience for customers. Additionally, the technology enables cost efficiency by reducing food waste and optimizing ingredient usage through precise measurements, contributing to sustainable kitchen practices.

| Applications | Description |

|---|---|

| Customized Menu | Tailoring dishes to meet individual preferences and dietary restrictions. |

| Cost Efficiency | Reducing food waste and optimizing ingredient usage through precise measurements. |

The ability to offer customized menu options not only enhances customer satisfaction but also provides a competitive edge in the culinary industry. Moreover, the cost efficiency achieved through reduced waste and optimized ingredient usage can lead to significant savings for professional kitchens. These applications underscore the potential of 3D printing to revolutionize the way food is prepared and presented in professional culinary settings.

Transitioning into the subsequent section about ‘considerations for implementing 3D printing’, it is essential to evaluate the practical aspects and challenges associated with integrating this innovative technology into professional kitchens.

Considerations for Implementing 3D Printing

Transitioning into the practical aspects and challenges of integrating this innovative technology into professional kitchens, it is crucial to consider the implications of implementing 3D printing in culinary settings. When preparing to introduce 3D printing into a professional kitchen, several key considerations should be taken into account:

-

Cost Efficiency: Assessing the initial investment, maintenance costs, and the overall cost-effectiveness of 3D printing technology in comparison to traditional culinary methods is essential.

-

Culinary Customization: Understanding the potential for creating intricate and customized culinary designs, and the extent to which this can enhance the dining experience for customers, is a pivotal aspect.

-

Regulatory Compliance: Ensuring that the 3D printing processes adhere to food safety and hygiene regulations is imperative for successful implementation.

-

Staff Training and Expertise: Providing comprehensive training for kitchen staff to effectively operate and leverage the full potential of 3D printing technology is crucial.

-

Integration with Existing Processes: Evaluating how 3D printing can seamlessly integrate with current kitchen operations without disrupting efficiency is vital.

Considering these factors is essential for a successful integration of 3D printing in professional kitchens, ensuring that the technology aligns with the culinary standards and business objectives.

As we delve into the future of 3D printing in culinary arts, it’s important to anticipate the potential impact of this innovative technology on the industry.

Future of 3D Printing in Culinary Arts

The integration of 3D printing technology in professional kitchens has paved the way for significant advancements in culinary arts. The future of 3D printing in culinary arts holds immense potential for culinary innovation. This technology is set to revolutionize the way food is prepared, presented, and experienced. It enables chefs to push the boundaries of creativity and design, offering opportunities for intricate and customizable culinary creations that were previously unimaginable. The table below illustrates some potential future applications of 3D printing technology in professional kitchens:

| Potential Applications of 3D Printing in Culinary Arts |

|---|

| Customizable Food Designs |

| Intricate Garnishes and Decorations |

| Personalized Nutritional Meals |

| Novel Texture and Flavor Combinations |

| Sustainable and Zero Waste Food Production |

These potential applications demonstrate the versatility and impact of 3D printing technology on culinary arts. As this technology continues to evolve, it is expected to further drive culinary innovation, allowing chefs to elevate their craft and offer unique dining experiences to patrons.

Frequently Asked Questions

How Does 3D Printing Affect the Taste and Texture of the Food Being Printed?

The impact of 3D printing on taste and texture of food varies based on factors such as ingredients, printing techniques, and post-processing. Understanding these factors is crucial in maintaining the desired sensory attributes in printed food.

What Are the Cost Implications of Implementing 3D Printing in a Professional Kitchen?

The cost implications of implementing 3D printing in professional kitchens are significant. While initial investment is required, efficiency benefits in production, reduced waste, and customization potential can lead to long-term cost savings.

Are There Any Health and Safety Concerns Associated With Using 3D Printed Food in Professional Kitchens?

Health concerns related to 3D printed ingredients in professional kitchens are paramount. Safety implications must adhere to professional kitchen regulations. Ensuring the materials used are food-safe and the printing process meets hygiene standards is crucial.

How Does 3D Printing Impact the Traditional Cooking Methods and Techniques Used in Professional Kitchens?

In professional kitchens, 3D printing impacts traditional cooking methods and techniques by enhancing culinary creativity and efficiency in food production. It introduces new possibilities for creating intricate designs and textures, streamlining processes, and optimizing ingredient usage.

What Are the Limitations of 3D Printing in Terms of the Types of Food That Can Be Printed?

Limitations of 3D printing in food include challenges in ensuring food safety, cost implications, and maintaining taste and texture. The technology’s current constraints in producing certain types of food may hinder its widespread adoption in professional kitchens.

Conclusion

In conclusion, food 3D printing is a groundbreaking innovation that is revolutionizing the culinary arts.

With its ability to create intricate and unique designs, it opens up endless possibilities for chefs to elevate their dishes to new heights.

As this technology continues to evolve, it will undoubtedly shape the future of professional kitchens, inspiring creativity and pushing the boundaries of what is possible in the world of food.