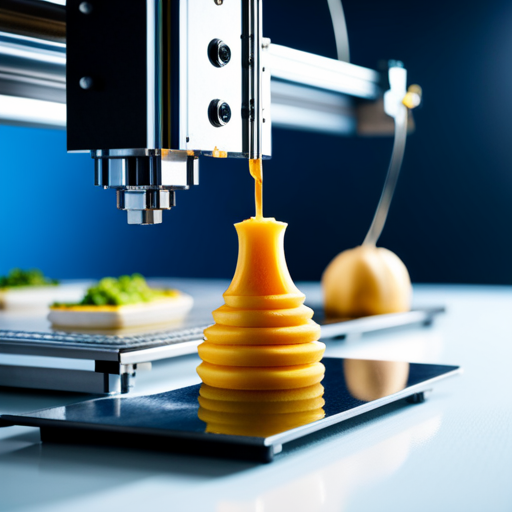

Curiosity surrounding the durability of food 3D printers has sparked a systematic investigation into their resilience and robustness. By meticulously examining the types, materials, components, and environmental factors, this study aims to provide a comprehensive understanding of their longevity and performance.

Through a methodical analysis, this exploration seeks to uncover the impact of usage frequency and volume, ultimately offering valuable insights into the comparative durability of food 3D printers across various price ranges.

Types of Food 3D Printers

There are several types of food 3D printers available in the market, each designed to cater to specific culinary needs. Custom designs, printing speed, cost efficiency, and design flexibility are key factors that differentiate these printers.

Some food 3D printers are tailored for creating intricate custom designs, allowing chefs and food enthusiasts to unleash their creativity in the kitchen. Others focus on printing speed, enabling quick production of edible decorations and intricate food designs.

Cost efficiency is a critical consideration for many, as it impacts the overall operational expenses in a culinary setting. Additionally, design flexibility is a crucial feature, allowing users to experiment with various shapes, textures, and flavors in their culinary creations.

Transitioning into the subsequent section about ‘material durability and compatibility’, it is essential to consider how these various types of food 3D printers handle different ingredients and ensure the longevity of the printed food items.

Material Durability and Compatibility

The durability and compatibility of materials used in food 3D printers are critical aspects that warrant thorough examination. Material strength testing is essential to ensure that the components of the 3D printer can withstand the demands of food printing processes.

Additionally, food safety considerations must be carefully evaluated to guarantee that the materials used are suitable for contact with consumable items.

Material Strength Testing

Several food 3D printers were subjected to material strength testing to assess their durability and compatibility with various food materials. Stress testing and performance evaluation were conducted to measure the printers’ ability to withstand different levels of stress and maintain consistent performance.

Material wear and impact resistance were also evaluated to determine how well the printers could handle the wear and tear associated with food 3D printing processes. These tests provided valuable insights into the longevity and robustness of the printers when dealing with different food materials, ensuring that they can maintain their structural integrity over time.

The results of these material strength tests offer crucial data for understanding the printers’ capability to handle various food items and the potential need for maintenance or replacement. Transitioning into the subsequent section, these material strength tests also have significant implications for food safety considerations.

Food Safety Considerations

During the material strength testing, the food 3D printers’ durability and compatibility with various food materials were assessed, which forms the basis for the subsequent discussion on food safety considerations concerning material durability and compatibility.

-

Material Safety: Ensuring that the materials used in 3D printing are food-safe and comply with relevant food safety regulations.

-

Hygiene Practices: Implementing strict hygiene practices to prevent contamination during the 3D printing process.

-

Material Compatibility: Assessing the compatibility of printing materials with different types of food to ensure safety and quality.

-

Long-term Durability: Evaluating the long-term durability of printing materials to prevent degradation and potential food safety risks.

-

Cleaning Procedures: Establishing effective cleaning procedures to maintain the hygiene and safety of the 3D printers and materials used.

These considerations are crucial in upholding food safety standards and ensuring the compatibility of 3D printed food with regulatory requirements.

Transitioning into the subsequent section about ‘components and build quality’, further analysis will be conducted.

Components and Build Quality

Analyzing the components and build quality of food 3D printers reveals crucial insights into their long-term performance and reliability. Component reliability and build quality assurance are essential factors in determining the overall durability and functionality of food 3D printers. A thorough assessment of these aspects is vital for ensuring the consistent production of safe and high-quality food items.

| Components | Build Quality |

|---|---|

| Extruder | Frame Structure |

| Nozzle | Stability |

| Filament Feeder | Material Durability |

| Bed Plate | Precision |

The table above provides a concise overview of key components and build quality aspects that significantly impact the performance and longevity of food 3D printers. The reliability of components such as the extruder, nozzle, filament feeder, and bed plate directly influences the printer’s ability to maintain consistent printing processes. Similarly, the build quality of the frame structure, stability, material durability, and precision plays a critical role in ensuring the overall reliability and durability of the 3D printer. By meticulously assessing these components and build quality factors, manufacturers can enhance the longevity and performance of food 3D printers, ultimately contributing to the safety and quality of the printed food products.

Longevity and Maintenance Considerations

As we transition to the topic of Longevity and Maintenance Considerations for food 3D printers, it is crucial to analyze the Printer Lifespan and Reliability, assessing the duration for which these machines can consistently perform at optimal levels.

Additionally, it is imperative to consider the frequency and associated costs of maintenance, as this directly impacts the operational efficiency and overall sustainability of the 3D printing process.

These points will be thoroughly examined to provide a comprehensive understanding of the long-term viability and practicality of different food 3D printers.

Printer Lifespan and Reliability

Throughout the lifespan of food 3D printers, the longevity and maintenance considerations play a crucial role in determining their reliability.

-

Lifespan Analysis: Conducting comprehensive assessments to determine the expected lifespan of the 3D printers based on their design, components, and usage patterns.

-

Performance Evaluation: Regularly monitoring and analyzing the printing performance to identify any deterioration or inefficiencies that may impact the printer’s lifespan.

-

Preventive Maintenance: Implementing a proactive maintenance schedule to address wear and tear, prevent breakdowns, and extend the overall lifespan of the printers.

-

Component Replacement: Identifying key components that are prone to wear and tear, and establishing protocols for timely replacement to ensure consistent reliability.

-

Firmware Updates: Ensuring that the printers are updated with the latest firmware to optimize performance, mitigate potential issues, and prolong their operational lifespan.

Maintenance Frequency and Cost

How frequently should maintenance be performed on food 3D printers, and what are the associated costs? Maintenance frequency and cost are crucial factors in determining the overall longevity and operational efficiency of food 3D printers. A well-structured maintenance schedule and cost analysis are essential for ensuring that the printers consistently produce high-quality food items while minimizing downtime and repair expenses. The table below provides a breakdown of the typical maintenance tasks and associated costs for food 3D printers.

| Maintenance Task | Frequency | Cost |

|---|---|---|

| Cleaning | Daily | Low |

| Calibration | Bi-weekly | Moderate |

| Component inspection | Monthly | Low to Moderate |

| Software updates | Quarterly | Low |

| Wear part replacement | As needed | Variable |

Understanding the maintenance frequency and cost is crucial for businesses to make informed decisions regarding the upkeep of their food 3D printers.

Moving on to the subsequent section about ‘environmental and operational factors’…

Environmental and Operational Factors

The environmental and operational factors affecting the durability of various food 3D printers are crucial considerations for manufacturers and users alike. When assessing the sustainability and longevity of these printers, several key factors come into play:

-

Environmental Impact: Understanding the environmental footprint of materials used in the printing process is essential. It involves considering the recyclability of printing materials and the overall impact on the environment.

-

Sustainability: Evaluating the long-term sustainability of the printer’s components and how they align with environmental goals is vital for the continued use of these machines.

-

Operational Efficiency: Assessing the energy consumption of the 3D printer during operation and identifying opportunities for improving efficiency.

-

Energy Consumption: Analyzing the energy requirements of the printer and identifying ways to minimize energy consumption without compromising printing quality.

-

Resource Management: Effectively managing resources such as water and electricity during the printing process to reduce waste and environmental impact.

Understanding and addressing these factors are critical for enhancing the overall durability and sustainability of food 3D printers. These considerations pave the way for a more comprehensive understanding of the environmental and operational impacts of these innovative technologies, setting the stage for further exploration into the impact of usage frequency and volume.

Impact of Usage Frequency and Volume

A thorough understanding of the impact of usage frequency and volume on the durability of various food 3D printers is essential for assessing their long-term sustainability and operational efficiency. Cleaning frequency plays a significant role in the wear and tear experienced by food 3D printers. High-usage frequency requires more frequent cleaning to maintain the printer’s components and ensure longevity.

Additionally, the volume of food material processed by the printer affects its durability. Higher volumes may lead to increased wear and tear on the printer’s mechanical and electrical parts, potentially reducing its operational lifespan.

The impact of usage frequency and volume extends beyond durability to encompass print quality and food safety. Increased usage frequency can lead to a decline in print quality due to the accumulation of food residues or debris. Moreover, higher usage volumes may raise concerns about food safety, as the printer’s components could degrade over time, potentially contaminating the printed food.

Therefore, maintaining an optimal balance between usage frequency, volume, and cleaning frequency is crucial to preserving the durability, print quality, and food safety of food 3D printers.

Comparing Durability Across Price Ranges

An analysis of durability across different price ranges reveals significant variations in the reliability and longevity of food 3D printers. When comparing the durability of food 3D printers across price ranges, several key factors come into play:

-

Material Quality: Higher-priced food 3D printers often utilize more durable and robust materials in their construction, leading to increased longevity and reliability.

-

Precision Engineering: Priceier models usually incorporate more precise engineering, resulting in reduced wear and tear over time and enhanced durability.

-

Advanced Components: Expensive food 3D printers are equipped with advanced components that contribute to their overall durability, ensuring sustained performance over extended periods.

-

Warranty and Support: Higher-priced models often come with better warranty coverage and customer support, adding an additional layer of durability through access to maintenance and service resources.

-

Long-term Cost Efficiency: Although the initial price may be higher, food 3D printers in the upper price ranges may offer better overall value due to their enhanced durability, resulting in reduced long-term maintenance and replacement costs.

The price comparison and durability assessment of food 3D printers highlight the importance of considering long-term reliability and robustness when making purchasing decisions.

Frequently Asked Questions

How Does the Durability of Food 3D Printers Compare to Traditional Kitchen Appliances?

When comparing the durability of food 3D printers to traditional kitchen appliances, it’s essential to consider their lifespan and material impact. Long-term reliability and material resilience are key factors in evaluating their durability.

Are There Any Specific Safety Considerations Related to the Durability of Food 3D Printers?

Safety considerations are paramount when using food 3D printers. Regular maintenance is crucial; clean the printer after each use to prevent contamination. Follow manufacturer guidelines for upkeep and use, ensuring safe and durable operation.

Can the Durability of Food 3D Printers Be Affected by the Type of Food Being Printed?

The durability of food 3D printers can be influenced by the type of food being printed, printing materials used, environmental factors, and maintenance practices. Considering these factors is crucial for ensuring food safety, optimal performance, and cost efficiency.

Are There Any Specific Maintenance Tips or Best Practices for Increasing the Longevity of Food 3D Printers?

To maximize the longevity of food 3D printers, adhering to specific maintenance tips and best practices is essential. Regular cleaning, calibration checks, and using high-quality printing materials are crucial for ensuring optimal performance and durability.

How Does the Durability of Food 3D Printers Impact the Overall Cost of Food Production?

The durability of food 3D printers significantly impacts the cost of production. High durability reduces maintenance expenses, ensuring long-term investment and production sustainability. It exemplifies the impact of technology on cost efficiency and operational reliability in food production.

Conclusion

In conclusion, the durability of various food 3D printers is influenced by a range of factors including material compatibility, build quality, maintenance, and environmental considerations.

Further research and testing are needed to fully understand the long-term durability of these printers across different price ranges.

As the demand for 3D printed food continues to grow, it is imperative to ensure that these printers can withstand the rigors of commercial and personal use.