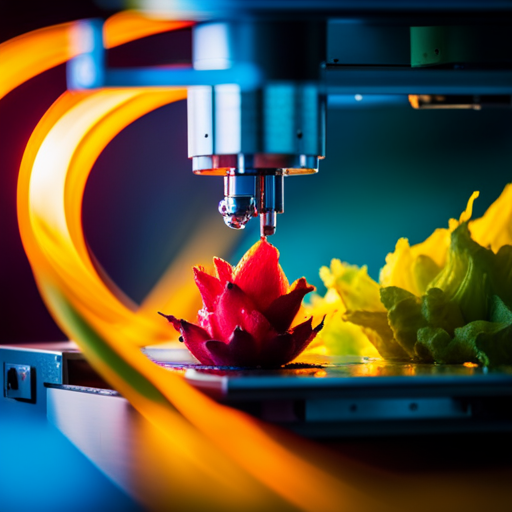

Revolutionizing culinary innovation, 3D printing with unique ingredients offers an unprecedented exploration of flavor profiles. This cutting-edge technology transcends traditional cooking methods, allowing for the creation of intricate, exotic dishes that push the boundaries of gastronomy.

With a focus on unconventional ingredients and their culinary applications, this article delves into the advantages and future implications of 3D printing in the realm of exotic flavors, offering a glimpse into the exciting possibilities of this innovative approach to food creation.

The Advantages of 3D Printing With Unique Ingredients

One primary advantage of 3D printing with unique ingredients is the ability to create customized and intricate designs that would be challenging or impossible to achieve with traditional manufacturing methods. Customized textures can be achieved by using a wide range of ingredients, including edible materials like chocolate, cheese, and dough, as well as non-edible materials such as ceramics and metals. With 3D printing, it is possible to precisely control the composition and placement of these ingredients, resulting in textures that are tailored to specific preferences or requirements.

Furthermore, 3D printing enables novel presentation techniques that can elevate the visual appeal of food and other products. For instance, intricate patterns, shapes, and structures can be produced with precision, allowing for visually stunning and unique presentations that captivate consumers. This level of customization and attention to detail is difficult to achieve through traditional manufacturing processes, making 3D printing with unique ingredients a game-changer in the world of culinary arts, product design, and beyond.

The ability to create bespoke textures and employ innovative presentation techniques opens up new possibilities for chefs, artists, and designers to express their creativity and offer truly distinct experiences to their audience.

Unconventional Ingredients for 3D Printing

Discussing unconventional ingredients for 3D printing extends the potential for chefs, artists, and designers to express their creativity and offer truly distinct experiences to their audience through precise control of composition and placement. When it comes to 3D printing with unique ingredients, edible insects and sustainable proteins are emerging as unconventional but highly innovative choices. Not only do these ingredients add a distinctive flavor profile to the printed creations, but they also contribute to the sustainability and eco-friendliness of the culinary arts.

| Unconventional Ingredients | Description |

|---|---|

| Edible Insects | High in sustainable proteins, vitamins, and minerals, edible insects such as crickets, mealworms, and grasshoppers are being used to create protein-rich 3D printed food items. |

| Sustainable Proteins | Ingredients like algae, seaweed, and plant-based proteins offer sustainable options for 3D printing, promoting environmental consciousness and providing a unique culinary experience. |

Incorporating these unconventional ingredients into 3D printing processes not only opens up new avenues for culinary exploration but also aligns with the growing demand for sustainable and eco-friendly practices in the food industry.

Transitioning into the subsequent section about ‘culinary applications of 3D printing’, the use of unconventional ingredients in 3D printing offers exciting opportunities for chefs to push the boundaries of culinary innovation.

Culinary Applications of 3D Printing

The incorporation of unconventional ingredients into 3D printing processes opens up new avenues for culinary exploration and provides chefs with exciting opportunities to push the boundaries of culinary innovation. 3D printing allows for the creation of customized dishes that are not only flavorful but also visually stunning. Chefs can now experiment with a wide range of unique ingredients such as edible flowers, exotic fruits, and rare spices, using them as the building blocks for intricate and artistic presentations.

One of the most significant advantages of 3D printing in culinary applications is the ability to design and produce complex shapes and structures that would be challenging to achieve using traditional methods. This opens up endless possibilities for presenting dishes in visually striking ways, enhancing the overall dining experience for patrons. Furthermore, 3D printing allows for precise control over portion sizes and ingredient placement, ensuring consistency in both flavor and aesthetics.

As the technology continues to advance, chefs will have even greater freedom to innovate and delight diners with extraordinary culinary creations.

Exploring Flavor Combinations in 3D Printing

Chefs are also exploring the future implications of 3D printing in gastronomy. This technology has the potential to revolutionize the way food is prepared and consumed. With the ability to create intricate and customized designs, 3D printing opens up new possibilities for presentation and aesthetics in the culinary world. Chefs can create visually stunning dishes that not only taste delicious but also look like works of art. Additionally, 3D printing has the potential to address issues of food sustainability and accessibility. By using alternative ingredients and reducing food waste, chefs can create more environmentally-friendly and inclusive dining experiences. The integration of 3D printing in gastronomy is still in its early stages, but it holds great promise for the future of food innovation. As technology continues to advance, we can expect to see even more exciting developments in this field.

Future Implications of 3D Printing in Gastronomy

Future implications of 3D printing in gastronomy extend beyond flavor experimentation to encompass a broad spectrum of technological advancements and culinary possibilities. The integration of 3D printing in gastronomy represents an exciting intersection of future technology and culinary innovation. As the technology continues to evolve, it has the potential to revolutionize the way food is prepared, presented, and consumed.

One major implication lies in the personalization of food. 3D printing allows for the creation of customized dishes tailored to individual preferences and dietary needs. This could lead to a new era of personalized nutrition, where meals are precisely designed to meet specific health requirements and taste preferences.

Additionally, 3D printing in gastronomy opens the door to intricate and visually stunning creations that were previously difficult to achieve using traditional methods. Chefs and food designers can leverage this technology to craft elaborate edible decorations, intricate structures, and artistic food presentations, pushing the boundaries of culinary artistry.

Furthermore, the integration of 3D printing with gastronomy may streamline food production processes, leading to increased efficiency and reduced waste in the food industry. This could have significant implications for sustainability and resource management within the culinary world.

Frequently Asked Questions

Are There Any Health Risks Associated With Consuming 3D Printed Food Made With Unconventional Ingredients?

Health risks associated with consuming 3D printed food made with unconventional ingredients are a concern. Safety regulations, taste testing, and texture analysis are essential to ensure the safety and palatability of such foods.

How Does the Taste and Texture of 3D Printed Food With Unique Ingredients Compare to Traditional Cooking Methods?

When comparing 3D printed food with unique ingredients to traditional cooking methods, taste comparison reveals nuanced flavor profiles. Texture analysis shows the potential for customized textures, creating new culinary experiences through innovative 3D printing technology.

Can 3D Printing With Unique Ingredients Accommodate Dietary Restrictions Such as Gluten-Free, Vegan, or Allergen-Free Options?

In exploring ingredient customization and culinary creativity, alternative food production through 3D printing offers a promising avenue for dietary inclusivity. It can cater to gluten-free, vegan, and allergen-free options, expanding the potential for personalized and inclusive gastronomic experiences.

What Are the Environmental Impacts of Using Unconventional Ingredients for 3D Printing in the Culinary Industry?

The use of unconventional ingredients in 3D printing for culinary applications raises concerns about environmental impact. Sustainable sourcing of these ingredients is crucial to mitigate potential negative effects and ensure a responsible approach to culinary innovation.

Are There Any Limitations or Challenges When It Comes to 3D Printing With Unique Ingredients, and How Are These Being Addressed by Researchers and Chefs?

Challenges in 3D printing with unique ingredients include texture, taste, and consistency. Innovations in material science and culinary creativity are addressing these, allowing chefs to experiment with unconventional ingredients in unprecedented ways, pushing culinary boundaries.

Conclusion

The use of unique ingredients in 3D printing offers a new frontier in gastronomy, allowing for unprecedented flavor combinations and culinary applications. According to a recent study, 3D printing in the food industry is projected to grow by 50% in the next five years, demonstrating the potential impact of this technology on the culinary world.

As the technology continues to evolve, the possibilities for creating exotic flavors and textures are endless.