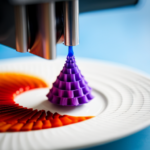

Redefining the culinary landscape, the intersection of technology and gastronomy has birthed a new wave of innovation in the form of food 3D printing.

Aspiring entrepreneurs seeking to capitalize on this burgeoning market are venturing into the realm of home-based food 3D printing businesses.

This article delves into the essential steps and considerations involved in establishing a successful venture, from selecting the right 3D printer to navigating food safety regulations and developing a robust marketing strategy.

Understanding Food 3D Printing Technology

Understanding the technology behind food 3D printing is essential for anyone looking to establish a home-based business in this innovative industry. Food 3D printing techniques involve the use of edible materials to create three-dimensional food products through a layer-by-layer printing process. This technology offers a wide range of potential market opportunities, including personalized confectionery, intricate cake decorations, and custom-shaped pasta and chocolates. By understanding the capabilities and limitations of food 3D printing, entrepreneurs can identify niche markets and cater to specific consumer demands.

The potential market opportunities for food 3D printing are vast, with the technology offering the ability to produce unique, customized food products that may not be easily achievable through traditional methods. This includes creating visually stunning and structurally complex food designs that can appeal to special events such as weddings, birthdays, and corporate gatherings. Additionally, the technology opens doors for meeting dietary restrictions and preferences, such as producing gluten-free or vegan-friendly delicacies.

Selecting the Right 3D Printer

When choosing a 3D printer for a home-based food printing business, several key factors come into play.

The printer’s size and capacity will determine the scale of food items that can be produced, while compatibility with food-safe materials is crucial for ensuring the safety of the printed items.

Additionally, a user-friendly interface is essential for streamlining the printing process and enabling efficient operation.

Printer Size and Capacity

Selecting the right 3D printer for a home-based food printing business requires careful consideration of printer size and capacity. When evaluating printers, several crucial factors need to be taken into account, such as:

-

Printer maintenance: Assess the ease of maintenance and cleaning to ensure smooth operation and food safety.

-

Food presentation: Consider the printer’s precision and capability to create intricate and visually appealing food designs.

-

Size limitations: Evaluate the maximum dimensions of the printed food items to ensure they meet your business’s requirements.

-

Production capacity: Determine the printer’s ability to meet the expected production demands without compromising on quality.

Considering these aspects will aid in selecting a 3D printer that aligns with the specific needs of a home-based food printing business.

Transitioning into the subsequent section, it is essential to address the compatibility of 3D printers with food-safe materials.

Food-Safe Material Compatibility

The compatibility of 3D printers with food-safe materials is a critical consideration when establishing a home-based food 3D printing business. Ensuring food material safety is essential to meet regulatory standards and produce edible items. When selecting a 3D printer, it’s crucial to consider the printing material options that are safe for food contact. Below is a table outlining some common food-safe 3D printing materials:

| Printing Material | Food-Safe Certification | Features |

|---|---|---|

| PLA (Polylactic Acid) | Generally Recognized as Safe (GRAS) | Biodegradable, low toxicity |

| PETG (Polyethylene Terephthalate Glycol) | FDA approved for food contact | Durable, transparent, and chemical resistant |

| TPU (Thermoplastic Polyurethane) | Food-safe certified | Flexible, strong, and resistant to oils and grease |

| Nylon | FDA approved for food contact | Tough, durable, and resistant to abrasion |

Carefully selecting a 3D printer that is compatible with these food-safe materials is essential for producing high-quality and safe edible items.

User-Friendly Interface Options

To ensure efficiency and ease of operation, it is imperative to consider the user-friendly interface options available when choosing the right 3D printer for a home-based food 3D printing business.

The user experience and interface design are crucial factors to consider, as they directly impact the usability of the 3D printer. When selecting a 3D printer, it is essential to prioritize accessible technology and usability testing to guarantee that the interface is intuitive and straightforward for users.

The following considerations can help in selecting a 3D printer with a user-friendly interface:

- Intuitive touch screen controls

- Simplified software interface

- Remote monitoring and control capabilities

- Easy maintenance and troubleshooting features

Sourcing High-Quality Food Ingredients

When building a home-based food 3D printing business, sourcing high-quality food ingredients is crucial. The standard of ingredients can significantly impact the taste and overall quality of the printed food.

Understanding the difference between local and imported ingredients can also influence the business’s sustainability and cost-effectiveness.

Ingredient Quality Standards

Sourcing high-quality food ingredients for a home-based food 3D printing business is essential for ensuring the final product’s safety and taste. When it comes to ingredient sourcing, the following aspects are crucial for maintaining quality and freshness:

-

Local and Organic: Prioritize sourcing ingredients from local and organic suppliers to ensure the highest quality and freshness.

-

Traceability: Choose suppliers that offer traceability of their products, allowing you to track the origin of the ingredients for quality assurance.

-

Food Preservation Methods: Select ingredients that have been preserved using natural methods, such as freezing or dehydration, to maintain their nutritional value.

-

Quality Certifications: Look for ingredients that have relevant quality certifications, ensuring they meet the necessary standards for consumption and processing.

Local Versus Imported Ingredients

Prioritizing local and organic ingredients for a home-based food 3D printing business is crucial for maintaining the highest quality and freshness, ensuring the safety and taste of the final products.

Local sourcing of ingredients offers the advantage of freshness and supports the community’s economy. While imported ingredients may provide a wider variety, they often come with higher transportation costs and a larger carbon footprint.

Additionally, local sourcing allows for direct communication with suppliers, ensuring the quality and authenticity of the ingredients. Cost comparison between local and imported ingredients is essential to determine the most economical option without compromising quality.

Designing Customized Food Creations

To design customized food creations, it is essential to understand the principles of food science and the capabilities of 3D food printing technology. When delving into customized food designs and innovative recipe development, several key factors come into play:

-

Ingredient Compatibility: Ensuring that the ingredients used in the 3D printing process are suitable for the technology and will yield the desired texture and flavor.

-

Structural Integrity: Designing food creations that not only look appealing but also maintain their shape and structure during the printing process and after consumption.

-

Flavor Infusion Techniques: Exploring methods to infuse flavors into various food materials to achieve a harmonious and palatable taste in the final printed products.

-

Health and Safety Considerations: Adhering to food safety regulations and guidelines when experimenting with novel ingredients and printing techniques to guarantee the safety of the end product.

Ensuring Food Safety and Compliance

As food entrepreneurs delve into the realm of 3D food printing, ensuring food safety and compliance throughout the production process and distribution chain becomes a paramount concern. Adhering to food safety regulations and providing compliance training for employees are essential elements in maintaining a successful home-based 3D food printing business.

| Key Aspects of Ensuring Food Safety and Compliance | Description |

|---|---|

| Food Safety Regulations | Familiarize yourself with local and national regulations to ensure that your 3D printed food products meet all safety standards. It is crucial to stay updated on any changes in regulations. |

| Compliance Training | Provide comprehensive training programs to all employees involved in the 3D printing process. These programs should cover sanitation practices, proper handling of ingredients, equipment maintenance, and emergency procedures. |

Developing a Marketing Strategy

Considering the importance of consumer trust and regulatory compliance, a strategic marketing approach is essential for home-based 3D food printing businesses to effectively showcase their innovative products and engage with potential customers. To succeed in the competitive market, businesses can implement the following strategies:

-

Social Media: Leveraging popular platforms like Instagram, Facebook, and TikTok to visually showcase the unique process of 3D food printing and the delightful end products. Engaging with followers through interactive posts, behind-the-scenes glimpses, and customer testimonials can help build a loyal customer base.

-

Influencer Partnerships: Collaborating with food and technology influencers who can create buzz around the innovative nature of 3D printed food. Influencers can promote products, share their experiences, and reach a wider audience, thus increasing brand visibility.

-

Content Marketing: Creating engaging and informative content through blogs, videos, and infographics to educate the audience about the benefits and possibilities of 3D printed food. This content can also highlight the customization options and sustainability aspects of this technology.

-

Community Engagement: Participating in local food festivals, farmer’s markets, and community events to offer live demonstrations and free samples, fostering direct interactions with potential customers. This can help in building trust and credibility within the local community.

Managing Operations and Logistics

Developing efficient operations and logistics is crucial for the success of a home-based 3D food printing business. Inventory management plays a vital role in ensuring that the necessary ingredients and materials are readily available to fulfill orders. It is essential to implement a system for monitoring stock levels and reordering supplies in a timely manner to avoid disruptions in production.

Additionally, establishing a streamlined delivery scheduling process is paramount to ensure that orders are delivered to customers promptly and in optimal condition. This may involve coordinating with reliable courier services and optimizing delivery routes to minimize transit times.

In terms of customer service, collecting and analyzing feedback is integral to improving the overall business operations. Actively seeking and responding to customer feedback can provide valuable insights into areas for improvement and help in refining the production and delivery processes.

Furthermore, maintaining open lines of communication with customers and promptly addressing any inquiries or concerns can contribute to building a loyal customer base. By prioritizing efficient inventory management, delivery scheduling, and customer service, a home-based 3D food printing business can ensure smooth operations and enhance customer satisfaction.

Frequently Asked Questions

What Are the Potential Legal and Regulatory Challenges of Running a Home-Based Food 3D Printing Business?

Ensuring legal compliance and food safety are critical aspects of running a home-based food 3D printing business. Potential challenges include navigating complex food safety regulations, obtaining necessary permits, and adhering to local zoning laws.

How Can I Ensure That My Customized Food Creations Are Both Visually Appealing and Delicious?

Visual presentation and taste testing are critical components of ensuring food creations are both visually appealing and delicious. Utilizing high-quality ingredients, experimenting with various flavors, and incorporating unique designs can enhance the overall appeal and taste of customized food creations.

What Are the Best Practices for Packaging and Shipping 3D Printed Food Products to Customers?

When it comes to packaging design, it’s essential to focus on safety, preservation, and aesthetics. Shipping logistics play a crucial role in ensuring timely and intact delivery. Careful planning and reliable carriers are key for successful shipping of 3D printed food products.

How Can I Effectively Target and Reach My Ideal Customer Base With My Marketing Strategy?

To effectively target and reach your ideal customer base with your marketing strategy, it’s crucial to conduct thorough market research, define your target audience, tailor your messaging to their needs, utilize various marketing channels, and continuously analyze and optimize your approach.

What Are Some Common Operational Challenges Faced by Home-Based Food 3D Printing Businesses, and How Can They Be Effectively Managed?

Common operational challenges faced by home-based food 3D printing businesses include maintaining operational efficiency and ensuring quality control. These can be effectively managed through streamlined production processes, rigorous quality checks, and continuous improvement initiatives.

Conclusion

In conclusion, building a home-based food 3D printing business requires:

- A thorough understanding of the technology

- Careful selection of a 3D printer

- Sourcing high-quality ingredients

- Designing customized creations

- Ensuring food safety and compliance

- Developing a marketing strategy

- Managing operations and logistics

It’s essential to stay ahead of the curve and adapt to new advancements in the field to remain competitive and successful in this fast-paced industry.